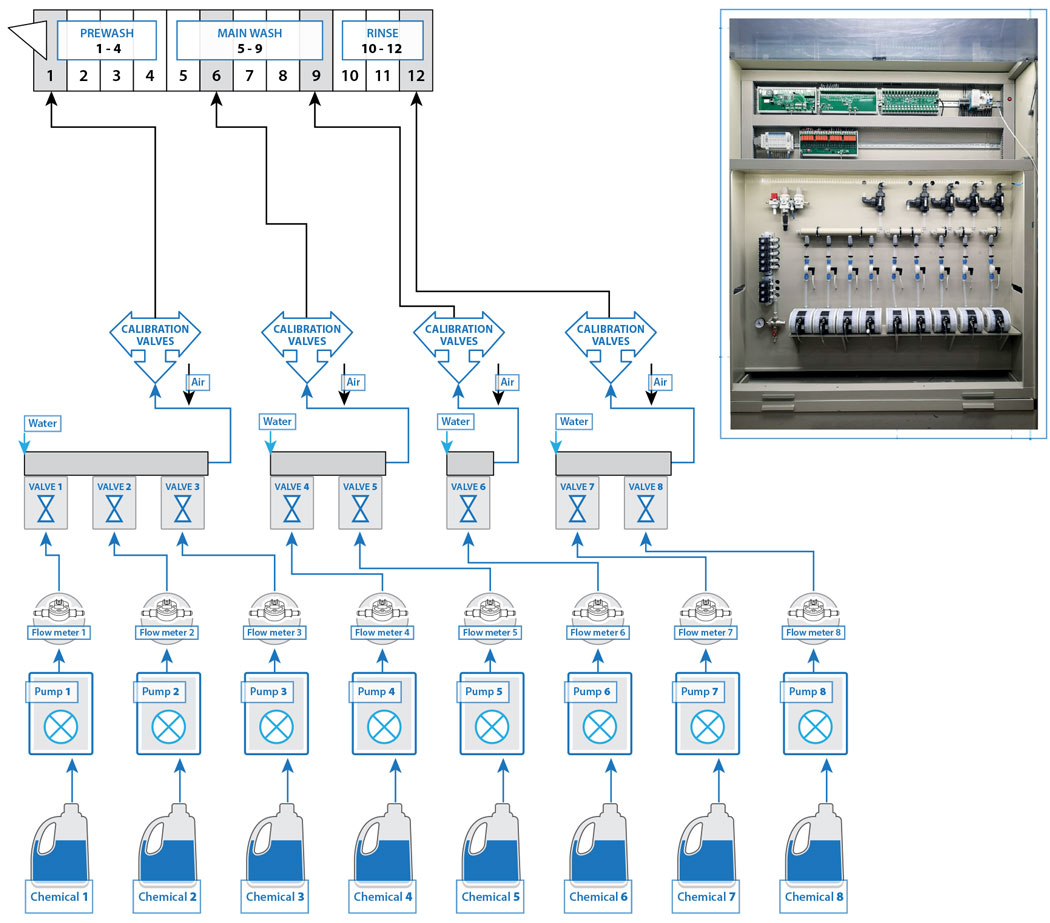

CTDS – 4 channels, 1 tunnel, 8 chemicals /pump per chemical/

Technical specifcation:

- 8 Pneumatic Pump (no limit)

- Control Cabinet

- 8 Flow meters (depends on the number of pumps)

- Unlimited number of chemicals

- Air flush (option)

Pump:

- NEW PFA type process pump (High corrosion resistance)

- Long service life. Diaphragms are made from denatured PTFE for superior resistance and longer service life

- Type: automatically or air operated

- Fluid: IPA, pure water, methyl ethyl ketone-hypochlorous acid soda

- Pilot air pressure: 0.2 to 0.5MPa

- Service life: 20 million cycles (or 12 months)

Valves:

- Manifold base for high purity chemical valve

- Stacking type manifold

- Common IN/Individual OUT

- Diaphragm (PTFE)

- Outstanding corrosion resistance. Compatible with chemicals such as acids, bases and ultra-pure water

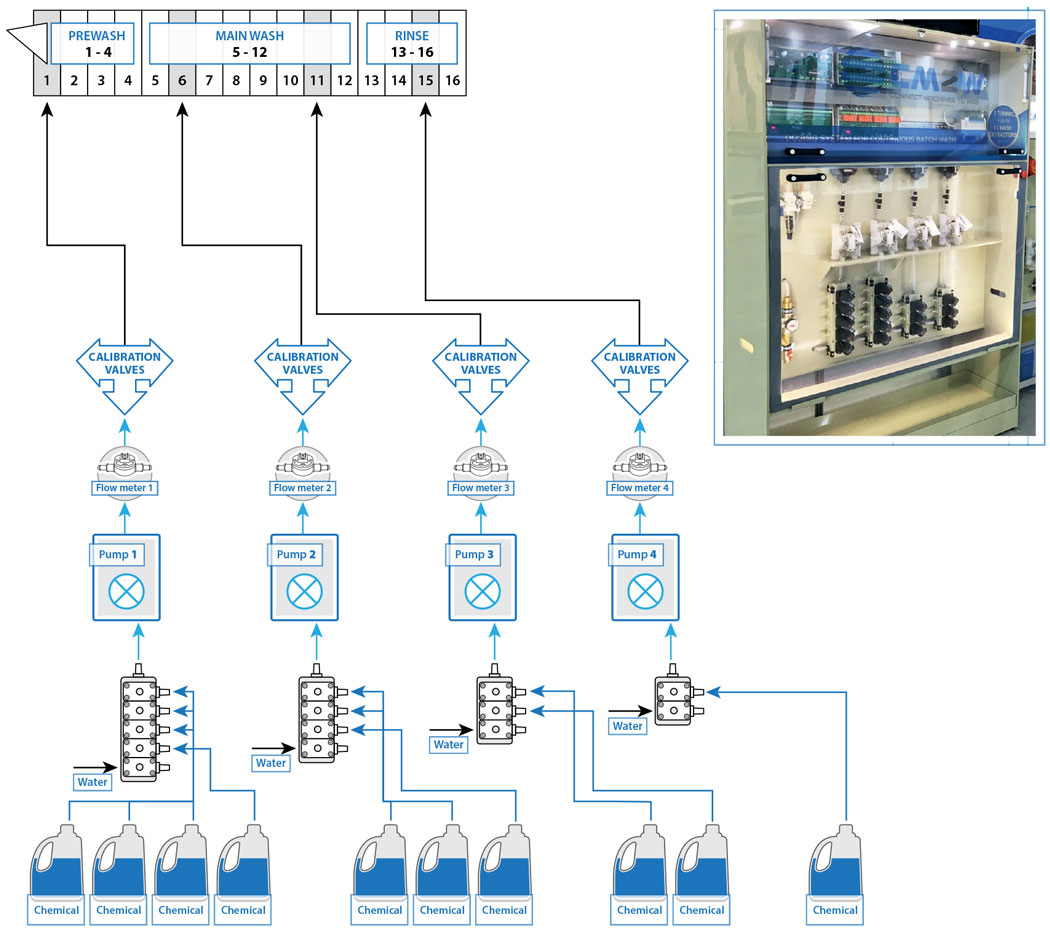

CTDS – 4 channels, 1 tunnel, 10 chemicals

Technical specifcation:

- 8 Pneumatic Pump (no limit)

- Control Cabinet

- 8 Flow meters (depends on the number of pumps)

- Unlimited number of chemicals

- Air flush (option)

Pump:

- NEW PFA type process pump (High corrosion resistance)

- Long service life. Diaphragms are made from denatured PTFE for superior resistance and longer service life

- Type: automatically or air operated

- Fluid: IPA, pure water, methyl ethyl ketone-hypochlorous acid soda

- Pilot air pressure: 0.2 to 0.5MPa

- Service life: 20 million cycles (or 12 months)

Valves:

- Manifold base for high purity chemical valve

- Stacking type manifold

- Common IN/Individual OUT

- Diaphragm (PTFE)

- Outstanding corrosion resistance. Compatible with chemicals such as acids, bases and ultra-pure water